SPECIFICATIONS:

WORKING CHAMBER

Height 600mm

width 600mm

Depth 600mm

DOOR OPENING

height 500mm

width 500mm

OVERALL DIMENSIONS

height 1660mm

width 800mm

depth 1500mm

DUST COLLECTOR(Fabric bag type manual shaking)

Fan Motor 1.5h.p

Fan capacity 400c.f.m

Filter cloth Area 2.0 sq. mt.

Injector office 3mm

Boron carbide Nozzle Short 6mm

Pressure gauge, air regulator &

Moisture separator fitted one no. each

Footswitch & door limit switch provided for safety interlocking

Compressed air required at 80 PSI 20 c.f.m

(for blasting machine only)

Abrasive storage capacity 28(1.0)ltrs. (CFT)

Abrasive feed Induction section

Recommended Abrasive Size 30 mesh to 220 mesh

SPECIFICATIONS:

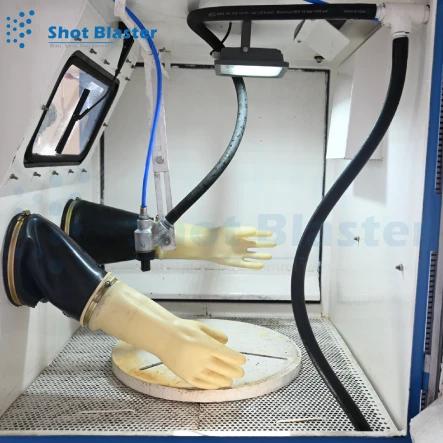

The wet blasting cabinet (Wet Blasting Machine) or high-pressure water blast cabinet is typically used for surface improvement, cleaning, preparation of coatings, deburring, and shot peening. It is made for finishing delicate, precision parts. Their circulation of the water/abrasive mixture achieves by high durability sludge pumps, which provide excellent technical and environmental benefits. It works on the reusable abrasive media process, which reduces the cost and time.

The wet blasting cabinet uses a seal-less slurry pump to convert the abrasive material and water into a slurry mixture. This slurry mixture is pump directly to the abrasive blast gun where compressed air pressure moves the mixture with the desired pressure rating.

The exhaust blower filter keeps a negative cabinet pressure that prevents the cabinet mist from leaving during the blasting process. During the process, freshwater is rinsed out on the window after fix interval of time which provides continuous operator visibility through the operator view window. Light enters the wet blasting cabinet through a sight window located on the top side of the sandblasting cabinet.