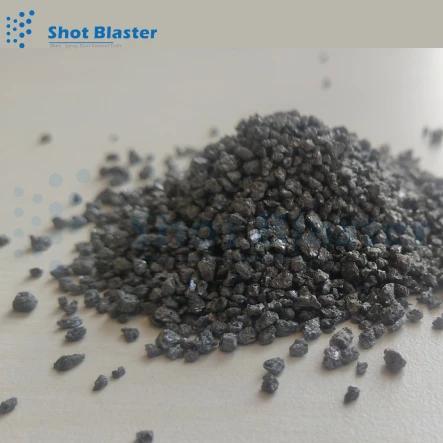

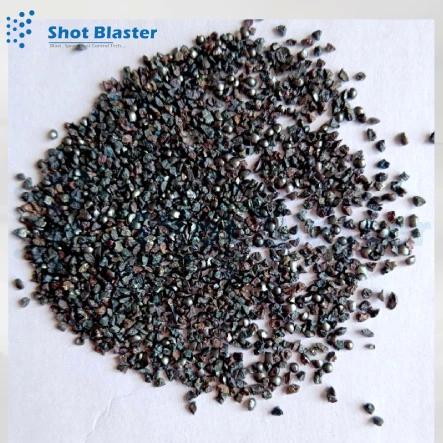

Silicon Carbide in India

Silicon carbide in India is a prolific choice for sandblasting, painting and other abrasive chores. Silicon carbide in India is employed in a number of sectors, including ceramics, electronics, and metallurgy. High-performance semiconductors and electrical components are frequently made from this extremely tough material because it can tolerate high temperatures. We as a profound provider of produce Silicon carbide in India at a range of forms, including grains, powders, and microgrits, for usage in a range of products, including abrasives, refractories, and advanced ceramics. Silicon carbide in India is employed, with the steel sector being the main driver of demand. Silica carbide grit is used in the steel industry as a deoxidizer and a desulfurizing agent to enhance the quality of steel.

Silicon Carbide Properties

With the chemical formula SiC, silicon carbide is a silicon and carbon combination. It is a ceramic substance having a number of distinctive qualities, such as, One of the toughest materials known, silicon carbide has a Mohs hardness of 9.5, making it a highly hard substance. Acids, alkalis, and molten salts are particularly resistant to chemically attacking silicon carbide. Due to its excellent thermal conductivity, silicon carbide can effectively disperse heat. Silicon carbide is a popular choice for blasting in sand blasting machine as per its durable nature and cost effective results. Wide bandgap semiconductor silicon carbide has high breakdown voltage, low leakage current, and high working temperatures, making it an ideal electrical material. Due to its hardness and abrasive qualities, silicon carbide is utilized as an abrasive in a variety of processes, including grinding, polishing, and cutting. Due to its strong radiation resistance, silicon carbide can be used in nuclear applications.

Silicon Carbide Uses

Silicon carbide for sandblasting is a very popular choice, and Silicon carbide blast media has a high degree of hardness and durability, making silica carbide grit a popular choice for abrasives. Silicon carbide blast media is utilized in sandpaper, grinding wheels, and other abrasive instruments. Being used within such vast sectors silicon carbide price per kg is more than affordable. Silicon carbide blast media is able to survive extreme temperatures and severe conditions. Refractory materials for furnaces and kilns are made using silica carbide grit. Silicon carbide blasting media is a perfect material for creating high-performance semiconductors and electronic components due to its outstanding electrical characteristics. Along with being super affordable silicon carbide is also heat resisting, this makes silicon carbide a good alternative of steel shots as well as other hard abrasives.

We, as a frontline silicon carbide manufacturers in India, and provide the highest-quality silicon carbide blast media to satisfy the particular needs of our customers. For the sand blasting and painting, silicon carbide blasting media is in great demand. The Silicon carbide quality is never compromised at our company since we are a provider that places a high priority on quality, hence our silicon carbide price per kg is satisfactory. We are one of India's leading silicon carbide supplier. The superfine-particle silicon carbide has a variety of applications.

Silicon Carbide manufacturers in India

As a silicon carbide manufacturers in India, we are adaptable and eager to meet the demands of our clients. To accommodate shifting needs, we modify our procedures and manufacturing plans. As a responsible silicon carbide manufacturer, we continually seek out innovative approaches and technologies and spend money on research and development. Being a leading silicon carbide manufacturer, our priority is to satisfy the demands of our clients, which includes offering first-rate customer support, considering their input, and creating products that specifically address their needs.

We provide steel shot, SS shot, copper slag, steel grit, garnet sand, quartz shot, aluminum oxide, glass beads, etc for the Sand Blasting Machine. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.