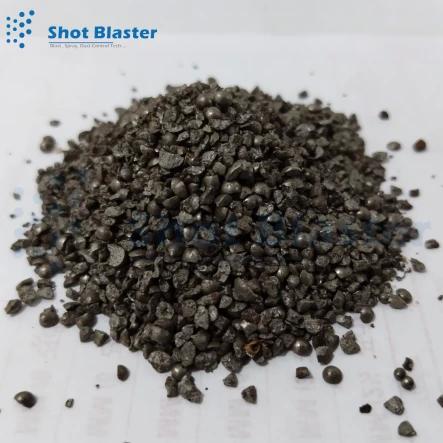

Chilled Iron Grits Manufacturer

Backed by the accomplished industrial experience and knowledge, we offer a quality assured range of Chilled Iron Grits manufacturer it by using top-notch quality components. These abrasives are suitable for etching structural steel and components. A few of the features of Chilled Iron Grits manufacturer are dense and hard, angular shape, lower breakage, quick cleaning action, and many more. Our clients can take benefits from us these high-grade abrasives at cost-effective prices.

| Hardness |

750 to 860 HRC (Hardness Rockwell C) |

| Micro Structure |

Martensite completely fine & uniform |

| Martensite completely fine & uniform |

7.5 gm./ml |

| Material |

Iron |

Chilled Iron Grits Sizes we have:

| G80 |

2.0-2.8 mm |

| G66 |

1.7-2.4 mm |

| G55 |

1.4-2.0 mm |

| G47 |

1.2-1.7 mm |

| G39 |

1.0-1.4 mm |

| G34 |

0.85-1.2 mm |

| G24 |

0.6-1.0 mm |

| G17 |

0.42-0.85 mm |

| G12 |

0.3-0.71 mm |

| G07 |

0.18-0.42 mm |

| G05 |

0.12-0.3 mm |

| G02 |

≤ 0.13 mm |

Physical Properties

- The hardness of new grain- ± 640 HV (56 HRC)

- Grain shape- Angular

- Density- Approx. 7,8 g/m³

- Bulk density (Dependent upon granular size)- Approx. 3,0 - 4,6 g/m³

- Microstructure- Martensitic

Chemical Properties

- C-2,80 - 3,20%

- Si- 1,00 - 1,50%

- Mn- 0,35 - 0,90%

- P- 0,10 - 0,20%

- S- 0,07 - 0,12%

- Fe- Remainder

Packaging

- 25 kg paper or plastic bags on pallet up to 1 ton.

- 1 ton loose in a bulk bag.

- Other packaging on request.

Chilled Iron Grits Manufacturer in India

We are the leading chilled iron grits manufacturer in India. We are also the supplier and exporter of abrasives such as glass beads, cut wire shot, copper slag, steel shot, aluminum oxide, and garnet sand. Our large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.

To enable us to quote for your requirement, kindly give us the following info –

1. Particle size required (You may choose from above or give your own range).

2. Packing required.

3. Quantity required with a delivery schedule.

4. Destination port.

5. Payment terms.

6. Discharge rate at the destination, if in break-bulk.

7. Any other point which may impact the quote.