Introduction of Cast Steel Grit

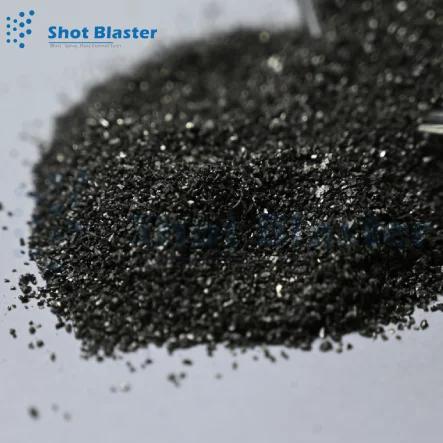

Cast steel grits are completed by melting cast iron observed by seed crushing & atomisation. The grains decompose into sharp-edged bits throughout the blasting process whichever supplies drift to grits caused by excessive hardness. Cast steel grit is hence excellent accompanied by roughening & heightened cleaning outcomes. These grits are angular in shape & keep a white texture, accompanied by a 1.7% & up to 3.5% carbon content.

Cast steel grit, manufactured underneath strict grade controls & conditions, utilizing a special air satisfying thermal process, whichever will produce a long-lasting abrasive media. accompanied by tiniest chloride & salt engagement, you obtain a blasting media accompanied by the most elevated outcome value for your cleaning application. Employed mostly in sand blasting machine operation for surface preparation before painting, it is likewise utilized for descaling & desanding applications.

Cast Steel Grit Abrasive

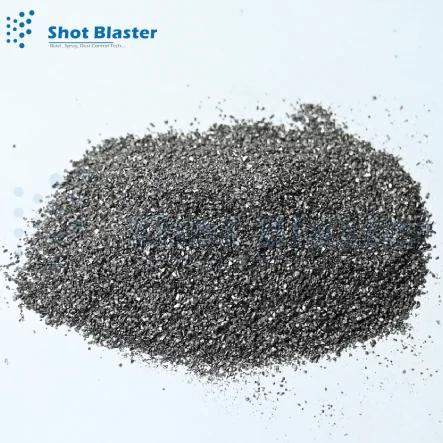

Cast steel grit abrasive is available in a assortment of shapes & sizes certain will assist in assisting a combination of blast profiles for acquiring additional results. This kind of grit is angular they way it includes been assembled. This grit is perfect for assisting to release adulterations from exterior of diverse outcomes & it also assembles a last shape for the unique coating to attach to. The numerous typical usefulness for steel grit are withdrawing of mill scale, drawing dissimilar grades of coatings from the surface of outcomes & specific grit sizes certain are numerous naturally employed coverage between G25 – G80. The more extensive the numeral of grits, the shorter size of the substantial bits of blast abrasive media.

The larger particles (the ones accompanied by lower G numbers) will deliver a more serious blast profile than the more diminutive particles, which in turn institute a trimmer blast profile on the outcome. Separated from the blast profile depth, larger particles exhibit greater efficacy in eliminating substantial paint layers, whilst more miniature bits are more appropriate for eliminating impurities on more delicate surfaces. This observation holds true when all different blast equipment environments stay the same: more extensive bits, such as G25, will escape more baritone profiles certain coverage betwixt 4 and 6 mils, whereas less bits, like G80 grit, will depart a 1-2 mil profile.

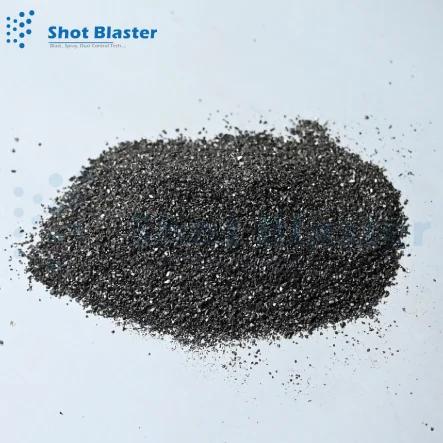

An different benefit concatenated to steel grit is certain it includes the possibility to be utilized numerous times before the essential of returning the grit arises. One can utilize automated abrasive blasting machine media recovery tools if one likes to recover & utilize the media again. This enables the media to be utilized nearly 150-200 times before it ought to be substituted accompanied by refreshed blast media.

The procedure of sand blasting has delivered many other methods to clean up, strip, & actually out exterior of dissimilar materials. Although the obsolete method of blasting- sand has currently lengthy been prohibited for usefulness due to its damaging silicosis, there is permanently a huge scope of considerably more unassailable substances certain to permit to construction of a flawless finish be it the restoring of portions of a composition & simply necessary refurbishing of slighter items.

Blasting is virtually of two major classes certain are numerous commonly utilized, whichever contain shot blasting & grit blasting machine. Both blasting procedures use separate kinds of materials but are usually assumed as a element of sand blasting to deliver an comprehensive outcome of their purpose.

To deliver a cost-effective & efficient blast cleaning procedure characteristics such as an essential familiarity of features of the steel blast cleaning abrasives, their appointment as well as use & the command of the blast cleaning machinery, its supervision & essential approach control features.

Applications of Cast Steel Grit

Industries in the metalworking business are the paramount users of cast steel grit & steel shot:

- Steel mills

- Ferrous & Nonferrous Foundries

- Forge shops

- Metal Fabricators

Cast Steel Grit Price in India

We are the leading cast steel grit manufacturer and also cast steel grit supplier in India. Cast steel grit price depends on the grade and size of steel grit in India. Our cast steel grit price is low compared to others. We also provide all types of abrasive blasting machines, automatic sand blasting machines, air-operated blasting machines, airless blasting machine, stone shot blasting machines, laser rust cleaning machines, granite engraving machines, dust collectors, air compressors, thermal spray booth, metal spray gun, abrasive media, high carbon steel shot, low carbon steel grit, cast steel grit, commercial aluminum oxide, glass beads, copper slag, plastic abrasive media, PS ball, etc.