Introduction of Boron Carbide Nozzle

The boron carbide nozzle is among the most durable and effective nozzles utilized in different abrasive blasting machine applications. They are highly valued for their intense hardness, wear resistance, and capacity to boost the life of equipment utilized in demanding environments. Boron Carbide Nozzles last a long time when used with the right air and abrasives. Boron carbide is superior for forceful abrasives like aluminum oxide and some mineral aggregates where rough handling is evaded. Boron carbide typically outwears tungsten carbide by five to ten times.

Boron carbide nozzles are even employed in surface preparation tasks, where they play a crucial role in assuring certain exteriors are properly cleaned and profiled before the application of coatings. This process is necessary in industries alike construction, shipbuilding, & manufacturing, wherever the bonding of protective coatings is vital to the longevity also performance of the finished product.

Boron Carbide Sandblasting Nozzle

Boron carbide sandblasting nozzle is extensively utilized in abrasive sand blasting machine, a process that involves moving abrasive media at heightened velocity to clean, etch, or prepare surfaces. These nozzles are particularly effective in releasing rust, scale, paint, and other surface contaminants from an assortment of materials, including metal, wood, stone, and glass. The superior wear resistance of boron carbide nozzles assures consistent performance and longer service life, even in the most abrasive environments.

In the shot peening machine, a process employed to enhance the fatigue strength of metal parts, the boron carbide nozzle is selected due to its capacity to handle the heightened velocity impact of shot particles without wearing them out. This application is critical in industries such as aerospace and automotive, where the durability and longevity of metal elements are paramount.

Due to their precision and durability, boron carbide nozzles are utilized in engraving and etching applications, particularly in the glass and dental industries. These nozzles could create intricate designs and details on hard surfaces without losing their sharpness or effectiveness over time, making them perfect for high-precision work

Properties of Boron Carbide Nozzle

- Extreme Hardness: Boron carbide is one of the hardest materials available, second just to diamond & cubic boron nitride. This creates boron carbide nozzles extremely resistant to wear and tear, assuring a longer service life corresponding to boron sand blasting nozzles assembled from additional materials like tungsten carbide & silicon carbide. The hardness of boron carbide, approximately 9.6 on the Mohs scale, is a preliminary factor in its widespread usage in demanding industrial environments.

- Lightweight and Durable: In addition to its hardness, boron carbide is also lightweight, with a density of about 2.52 g/cm3. This combination of lightness and durability makes boron carbide nozzles easy to handle while offering excellent performance in heightened-pressure blasting environments. The reduced weight also minimizes operator fatigue during prolonged use, making these nozzles excellent for extended industrial applications.

- Chemical and Thermal Resistance: Boron carbide nozzles are extremely resistant to chemical reactions and can tolerate high temperatures, making them superior for usage in settings where other materials may decay. This chemical inertness assures certain the nozzles do not react with the abrasive media and the exterior being treated, preserving structural integrity and performance over time.

A boron carbide sandblasting nozzle is the optimum option, specifically for stationary applications and when utilizing aggressive blasting material like corundum (aluminum oxide). The durable boron carbide liner allows for a longer nozzle lifetime than further liner materials, making it exceptionally cost-effective, particularly in skilled blasting procedures and continued use.

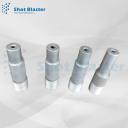

Our boron carbide blast nozzle with natural rubber jackets is known in nozzle diameters ranging from 6-10mm and operates the Venturi impact to maximize blast media exit speed. This improves blasting interpretation and, as a result, maximizes surface preparation.

Advantages of Boron Carbide Nozzle

- Longevity and Cost Efficiency: One of the primary advantages of boron carbide nozzles is their extended lifespan. These nozzles could last significantly longer than those assembled from further materials, such as tungsten carbide, whichever translates into lower overall costs due to fewer replacements and less downtime.

- Consistency in Performance: Boron carbide nozzles maintain a consistent spray pattern and abrasive flow rate over time, ensuring uniform results across large surface areas. This consistency is important in applications requiring precision and uniformity, such as in coating preparation or exterior finishing.

- Reduced Downtime: The durability of boron carbide nozzles decreases the frequency of nozzle changes, which in turn minimizes downtime during operations. This increased operational efficiency is particularly beneficial in industries where time and productivity are critical factors.

When comparing boron carbide nozzle with those created from additional materials, such as tungsten carbide and silicon carbide, several advantages stand out. While tungsten carbide nozzles are even durable, they typically have a shorter lifespan compared to boron carbide. This difference in longevity makes boron carbide a more cost-effective choice in the long run, despite its higher initial cost.

Boron Carbide Nozzle in India

In India, we are the top boron carbide nozzle manufacturer and supplier of boron carbide nozzle. In comparison to others, our boron carbide nozzle price is reasonable. Our boron carbide nozzle price ranges from 3 to 20k. Additionally, we provide an automatic sand blasting machine, shot blasting machine, sand blasting nozzles, sand blasting helmet, sand blasting spare parts, granite stone engraving machine, abrasive media, steel shot, steel grit, white aluminum oxide, plastic abrasive media, copper slag, PS ball, mineral powder, dolomite powder, limestone powder, calcite powder, etc. in addition to thermal spray guns, thermal spray booths, paint spray booths, and thermal spray wire.