Steel Grit Manufacturer

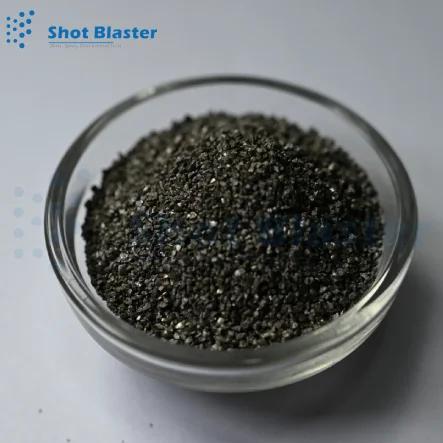

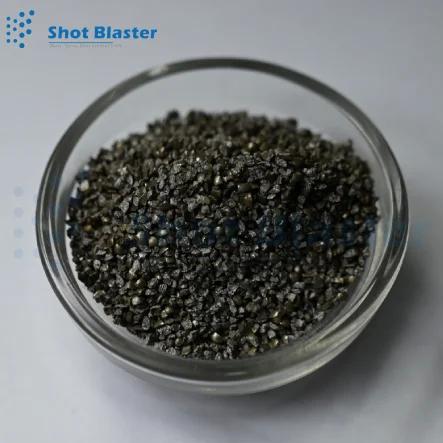

Steel grit is fabricated by crushing, screening the resulting abrasive media, and tempering it to the desired hardness. These abrasive Steel Grits are specially used in every type of wheel machine and also for blast room where nozzles are employed in air blasting. Their sharp edges help in cleaning, etching, and smoothening of the blasting surface easily.

Steel grits are used as an abrasive blast media in grit blasting machine. Blasting with steel grit an important operation of metal production. Steel grit are most commonly used to meet different requirements for many industrial applications. Steel grit produces an etching on the surface of the substrate for better coatings. Steel grit manufacturer is angular in shape. Steel grit used to remove old paint, rust, and other hard contaminants from the surface of the substrate. Mostly steel grit used for removing mill scale and different degrees of coatings from the surface. As steel grits are angular in shape so they remove old paint easily but if the component material is soft then there will be chances of damage. So the selection of steel grit is depended upon the component material and also the purpose of the blasting process to be done. Steel Grit manufacturer is present in a variety of shapes and sizes. Variety in the shape and size of a steel grit allows a variety of blast profiles for obtaining different results. Commonly steel grit always used to remove mill scale, removing different degrees of coatings from the surface of products, and typical grit sizes that are most commonly used range between G25 – G80. As the number of steel grit increases the smaller will be the size of the actual particle of blast media.

|

MODEL

|

HARDNESS

|

MICROSTRUCTURE

|

DENSITY

|

EXTERNAL FORM

|

|

GH40

|

63-65hrc

|

TROOSTITE

|

>7.40g/cm3

|

Angular (spherical, semi-spherical, flat granules<10%)

|

|

GH140

|

56-60hrc

|

TROOSTITE

|

>7.40g/cm3

|

Angular (spherical, semi-spherical, flat granules<10%)

|

|

GP40

|

40-50hrc

|

TROOSTITE

|

>7.40g/cm3

|

Angular (spherical, semi-spherical, flat granules<10%)

|

Small particle size steel grit creating a smaller blast profile onto the surface of the substrate and a large size particle is creating a deeper blast profile on the surface of the substrate. Large size particles are more effective to remove heavy amounts of paint while the small size of particles is more suitable to remove containments. Steel grit manufacturer is used in the blasting process with both compressed air and a blasting wheel. Steel grit can be used many times to form a blasting process. As steel grit present in different size so nozzle and compressed air is also determined. Which size steel grit use depends upon the size of the nozzle used, compressed air availability, and the purpose of blasting. Steel grit expensive blasting media so to reuse this grit blast room system and grit blasting cabinet is a more suitable option to collect the media after blasting.

|

s. no.

|

SAE NO.

|

SCREEN APERTURE

(SIZE IN mm)

|

|

1

|

G-70

|

0.120

|

|

2

|

G-80

|

0.180

|

|

3

|

G-50

|

0.300

|

|

4

|

G-40

|

0.425

|

|

5

|

G-30

|

0.600

|

|

6

|

G-25

|

0.710

|

|

7

|

G-20

|

0.850

|

|

8

|

G-18

|

1.00

|

|

9

|

G-16

|

1.18

|

|

10

|

G-14

|

1.40

|

|

11

|

G-12

|

1.70

|

|

12

|

G-10

|

2.00

|

Steel Grit Manufacturer Applications

- Shot blasting.

- Shipbuilding.

- Pipe building.

- Steel construction.

- Granite cutting.

- Metal fabrication.

- Steel mills.

Steel Grit Manufacturer Advantages

- Superior hardness.

- Maximum durability.

- Impacts energy transfer.

We are a Manufacturer, Supplier & Exporter of Steel shot, Steel grit, Abrasive Garnet at a low price for Sale. We are also a Manufacturer of Sand Blasting Machine, Shot Blasting Machine, Sand Blasting Cabinet, Shot Blasting Room, Pressure Blasting Cabinets in Jodhpur, Rajasthan India with the best quality at a low price for sale. We represent and offer the best supplies of surface finishing equipment and Abrasives and we provide a trustworthy service with a great experience. our focus is on client satisfaction and happy customers.