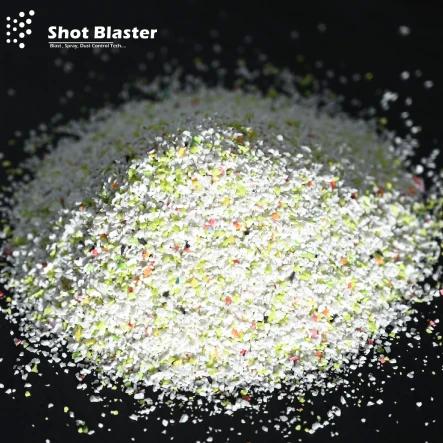

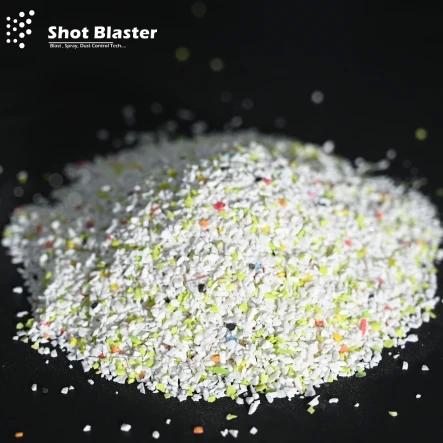

Abrasive Plastic media

Abrasive Plastic media of sand blasting machine supplier of Five -grades of hardness for efficient and economical paint removal, and coating for the workpiece, blast cleaning, de-flashing, and deburring. Plastic Blast Media offers superior cutting action and results without breaking or damaging even delicate surfaces. Plastic media abrasives are also usually used as anti-slip features in paints, cement, coatings, and non-skid whole formulations.

The use of plastic media abrasives in sandblasting was originally raised by the military to replace deadly chemical strippers for the stripping of aircraft and aerospace components or parts of the jobs. Up until the early 1980s, the most common method of paint removal was chemical stripping. Plastic media blasting offered major improvements in environmental and worker safety; provided important operational savings, and quickly became a selected method of paint and coatings removal.

The Plastic media are given in different mesh and micron as shown in the table. The table below shows the relative size in inches and microns for different mesh sizes. These values are generally accepted as correct but are approximates because the thickness of the cut wire shots are used to make a specific screen will vary the number of openings in one square inch. In a micron is one-millionth of a meter or one-twenty-five thousandths of an inch. Most grades below 325 mesh are registered by the micron size as these sizes are not produced or manufactured using screens.

Abrasive Plastic Media Size Details

| Mesh |

Micron |

Inches |

Mesh |

Micron |

Inches |

Mesh |

Micron |

Inches |

| 4 |

4,750 um |

0.187 |

36 |

485 um |

0.019 |

180 |

76 um |

0.003 |

| 5 |

4,000 um |

0.157 |

40 |

425 um |

0.016 |

200 |

75 um |

0.0029 |

| 6 |

3,350 um |

0.132 |

46 |

355 um |

0.014 |

220 |

63 um |

0.0025 |

| 7 |

2,800 um |

0.111 |

54 |

305 um |

0.012 |

240 |

53 um |

0.002 |

| 8 |

2,360 um |

0.0937 |

60 |

250 um |

0.01 |

280 |

44 um |

0.0015 |

| 10 |

2,000 um |

0.0787 |

70 |

210 um |

0.0083 |

320 |

36 um |

0.0012 |

| 12 |

1,700 um |

0.0661 |

80 |

165 um |

0.0065 |

400 |

23 um |

0.00087 |

| 14 |

1,400 um |

0.0555 |

90 |

149 um |

0.0059 |

500 |

19 um |

0.00075 |

| 16 |

1,200 um |

0.0473 |

100 |

145 um |

0.0057 |

600 |

16 um |

0.00063 |

| 18 |

1,000 um |

0.0394 |

120 |

125 um |

0.0049 |

800 |

12 um |

0.00047 |

| 20 |

850 um |

0.0331 |

140 |

105 um |

0.0041 |

1000 |

9 um |

0.00028 |

| 24 |

690 um |

0.027 |

150 |

89 um |

0.0035 |

1200 |

6 um |

0.00024 |

| 30 |

560 um |

0.022 |

170 |

88 um |

0.0031 |

The density of media is 1.5 to 1.20g/cc and the hardness of plastic media are lies between 3.2 to 3.5 HRC. The particles of plastic media are got in surf excel or detergent because it is a very softer rubber type. The plastic media are available in multicolor. it helps us don’t rinse them in the water and hands it helps us smoother the clothes and hands from a chemical detergent so it's mix with detergent.

Abrasive Plastic Media Application Areas

Plastic media is mainly used to remove paint from cars, trucks, airplanes, boats, ships, trains, helicopters, and all types of dust particles components and parts of Using plastic media blasting to remove powder coatings from parts. In contrast, PMB (plastic media beads ) is an effective method for stripping all types of metals.it is very softer to use and effectively used for sandblasting machine, shot blasting machine, sand blasting hopper.

Blasting with plastic media provides supply operators with the ability to remove paint and coatings from aluminium and steel, without warping, marring, or pitting surfaces; or damaging mechanical functions, bearings, or seals. Plastic media leaves surfaces stripped smooth for new paint just to remove coating and paint and coating applications. Strong abrasives such as sand, steel shots, and aluminium oxide, abrasive garnet, steel grit can damage surfaces, however, plastic blast media abrasives of sandblasting offer superior solutions for efficient paint removal without damaging or breaking even delicate and sensitive surfaces when using recommended blast parameters.

Abrasive Plastic Media Manufacturer in India

We are an abrasive plastic media manufacturer in Jodhpur, Rajasthan, India. We are the leading manufacture of sandblasting machine, Shot blasting machine, Sand blasting hopper, metalizing wire, wire flame spray gun, zinc spray gun, thermal spray gun, arc spray gun, twin arc spray gun, metalizing gun, flame spray gun, zinc metalizing wire, zinc aluminum metalizing wire, and blasting media like abrasive garnet, copper slag, steel shots, cut wire shots, whip check at low price in India.